Fundamental Mistakes in 5S – Part 1

1. Not doing why-why analysis after 1S activity

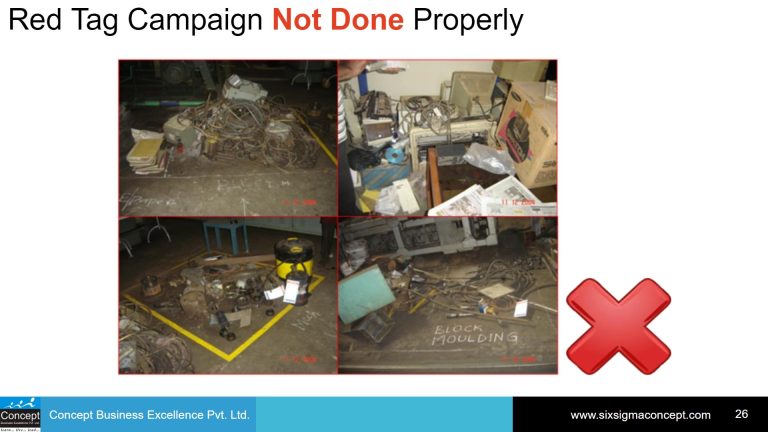

“Putting “Red Tag” and keeping the items in Red Zone is not enough” In a large machine manufacturing company when we did Red Tag campaign, we found more than 2178 tags. But we just did not stop at putting those Red Tag items in Red Tag area and taking decision to either

Scrap / Dispose / Recycle

Repair / Rework / Resuse

Send to right location / Vendor

We decided to do “Why’Why” analysis for some critical Red Tag items. To our surprise we found following root causes:

Incident 1 BOM (Bill of Material) mismatch. Actual BOM and BOM in SAP did not match. SAP BOM was having more items than actual BOM. Every time the company used to run MRP (Material Resource Planning), SAP would raise PO for those items. When we did deep investigation we found there were 139 items like that. Corrective Action was to update BOM and link BOM to Design ECN (Engineering Change Note)

Incident 2 In another incident, we found lot of old cataloges of exhibition lying in a room. The root cause was that each of those cataloges were having year of exhibition printed, so cant be used. The corrective action applied was 1) not to print year of exhibition, so surplus stocks can be used next year and 2) do proper analysis of usage of cataloge and only print required cataloges.

So next time you do 1S (Seiri) activity just do not focus on putting red tag and throwing items. Do Why-Why analysis and find root causes too. Correct the system also.

Keep improving!