For many organizations, 5S has been reduced to a one-time cleaning drive or a poster on the wall. But in reality, 5S is not about housekeeping. It is the foundation of Operational Excellence, and without it, no Continuous Improvement initiative can truly sustain.

As we move deeper into 2025, organizations that excel in efficiency, safety, and customer experience all have one thing in common:

They treat 5S as a mindset, not a project.

The Misunderstanding That Holds Organizations Back

When leaders hear “5S,” they often think of:

✔ cleaning days

✔ labeling tools

✔ organizing cupboards

But the purpose of 5S goes far deeper.

The real goal is to design a workplace that enables flow, removes friction, and empowers people to do their best work.

When teams understand this, 5S stops being a compliance routine and becomes a strategic enabler.

Why 5S Matters More Than Ever in 2025

Today’s business environment demands:

🔹 Faster decision-making

🔹 Zero delays and zero defects

🔹 Leaner operations

🔹 Higher predictability

🔹 Safer workplaces

🔹 A culture where teams own the process

5S supports each of these by creating a workplace where everything has a purpose and everything has a place.

When the environment is clear, the mind is clear.

When the mind is clear, performance accelerates.

5S as a Driver of Operational Excellence

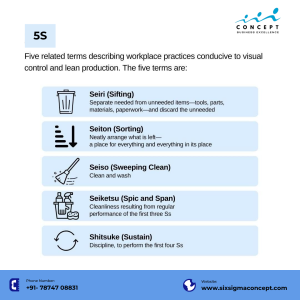

Let’s rethink what each “S” truly stands for in an OpEx-driven organization:

1. Sort (Eliminate the clutter)

Remove what does not add value. Clutter is not just physical—it includes digital chaos, unnecessary steps, redundant approvals, and outdated habits.

2. Set in Order (Design for flow)

Optimize the arrangement of tools, information, assets, and digital systems for minimal motion and maximum flow.

3. Shine (Create ownership)

Shine is about maintaining standards daily—not just cleaning. It builds accountability, discipline, and pride in the workplace.

4. Standardize (Build repeatable success)

Standardization creates consistency, reduces variability, and helps onboard new employees faster.

5. Sustain (Create culture)

This is where most organizations fail. Sustain means systems, rituals, audits, and leadership behaviors that make 5S a part of everyday work.

The Hidden ROI: What Organizations Gain When 5S Is Done Right

Organizations that implement 5S effectively experience:

💡 15–30% higher productivity

💡 Reduced searching and waiting time

💡 Lower defect rates

💡 Safer work environments

💡 Higher employee ownership and engagement

💡 Stronger foundation for Lean, Kaizen, TPM, and Digital Transformation

These results aren’t accidental—they come from disciplined, sustained workplace design.

Where to Begin: A Practical Starting Point

If your organization wants to move beyond surface-level 5S, start with:

-

A 5S maturity assessment (identify your gaps)

-

Hands-on training for leaders and teams

-

Pilot 5S zones to create early success stories

-

Visual management systems

-

Regular 5S audits and coaching

-

Celebrate wins to build momentum

Change doesn’t happen in one large step—it happens through small, consistent improvements.

The Bottom Line

5S is not a cleaning activity.

It is a strategic discipline that helps organizations eliminate waste, design flow, build ownership, and accelerate their journey toward Operational Excellence.

Companies that truly embrace 5S don’t just organize their workplace—they transform their culture.

To know your organization’s OpEx Maturity – Try our FREE assessment tool OpEx Maturity Model : https://omm.cbepl.com/