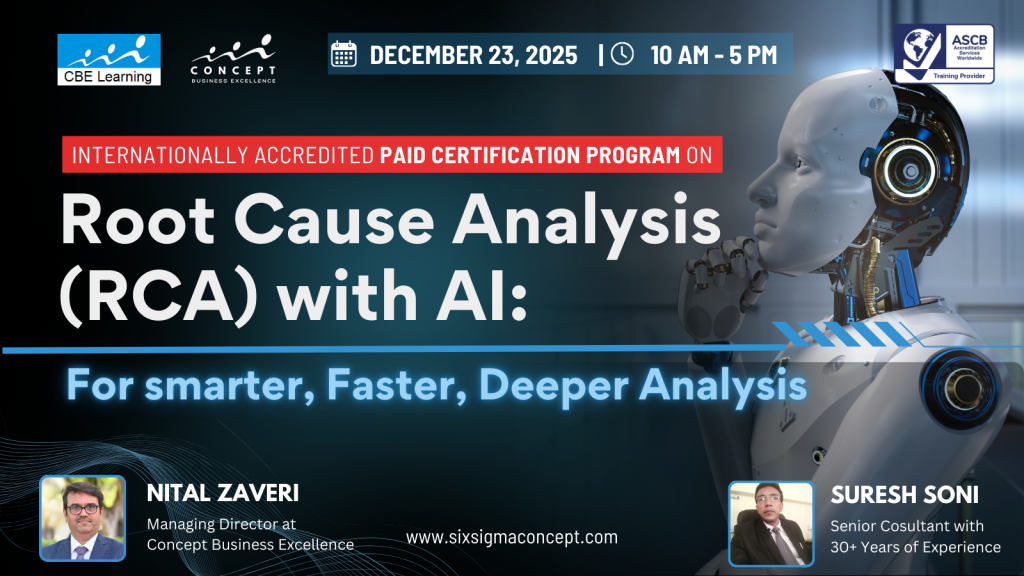

About Root Cause Analysis (RCA) with AI : For smarter, Faster, Deeper Analysis : PAID Program

- This Paid program equips professionals with practical tools to identify and eliminate root causes using proven techniques like 5 Whys, Fishbone Diagram, Pareto Analysis, FMEA, and more. It also explores how AI and NLP enhance RCA through faster, data-driven insights and analysis of unstructured data.

- Participants will gain hands-on experience through real-world case studies and exercises, enabling them to reduce defects, minimize downtime, and drive lasting improvements across processes.