Transform Your Processes. Eliminate Waste. Improve Flow.

In today’s competitive and fast-evolving business environment, organizations must deliver faster, better, and more efficiently than ever before. Value Stream Mapping (VSM) is a proven Lean methodology that enables organizations to visualize, analyze, and optimize the flow of materials and information across the value chain.

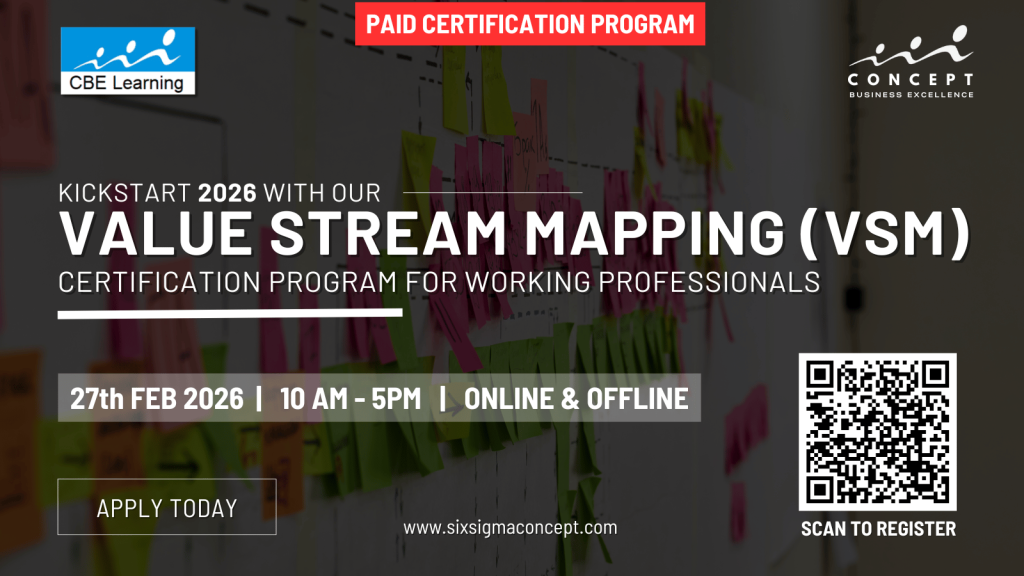

The Value Stream Mapping (VSM) Certification Training by CBE Learning is a hands-on, practitioner-focused program designed to help professionals identify waste, improve throughput, and design future-state processes that deliver measurable business results.

About Value Stream Mapping (VSM)

Value Stream Mapping—also known as material and information flow mapping at Toyota—is a core Lean tool used to analyze the end-to-end flow of activities required to deliver a product or service to the customer.

This certification program equips participants with the capability to:

Develop Current State Value Stream Maps using real data

Identify bottlenecks, delays, and non-value-added activities

Design an effective Future State Map aligned with business goals

Create actionable implementation plans to achieve operational excellence

The program is applicable across manufacturing, supply chain, service, IT, and transactional processes.